Access the full potential of your metal fabrication process with our advanced NC Shearing Machine, designed for precision, productivity, and long-term reliability. As a leading NC Shearing Machine Manufacturer and Supplier, we provide cutting-edge solutions that meet the diverse needs of modern industries. Whether you’re shearing thin sheets or thick plates, our NC shearing machines deliver consistent, high-quality results, ensuring seamless integration into your production line and helping you achieve superior outcomes with every cut.

Why Choose Our NC Shearing Machine?

Our NC shearing machines are engineered to optimize efficiency, minimize material waste, and deliver exceptional cut quality, making them an invaluable asset for modern fabrication shops. Here’s what sets us apart as a premier NC shearing machine manufacturer and reliable NC shearing machine supplier:

- Unmatched Precision Cutting: Achieve clean, accurate cuts with minimal burrs using our advanced NC shearing machine, thanks to variable rake angle technology and NC-controlled precision back gauge systems.

- Versatile Performance Across Industries: Designed for a wide range of materials like mild steel, stainless steel, aluminum, brass, and copper, our NC shearing machine is ideal for industries such as automotive, construction, and aerospace.

- Robust and Durable Construction: Built with high-quality components like hardened ball screws and linear motion bearings, our NC shearing machines ensure durability and reliability, a hallmark of our expertise as an NC shearing machine manufacturer.

- User-Friendly NC Controller: Equipped with an intuitive NC controller, our NC shearing machine allows easy programming of back gauge positions, stroke length, and stroke counting, enhancing productivity.

- Customizable Configurations: As a dedicated NC shearing machine supplier, we offer tailored solutions to meet your specific requirements and workflows.

Key Features of Our NC Shearing Machine

Our NC shearing machines are packed with advanced features that ensure exceptional performance. Here’s a detailed look at the technology and capabilities that make our machines stand out:

Variable Rake Angle Design

The variable rake angle design in our NC shearing machine offers flexibility for cutting both thin and thick sheets with precision. The NC controller enables automatic rake angle adjustment based on material thickness and type, delivering:

- Better cutting accuracy on thin sheets at lower rake angles.

- Higher cutting capacity at maximum rake angles for thicker materials.

- Reduced distortion and cleaner cuts, even on challenging materials like high-tensile steel.

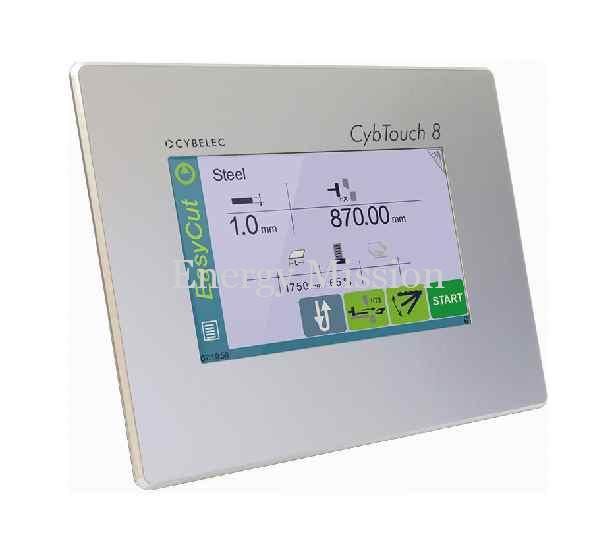

Advanced NC Controller

Our NC shearing machines feature a user-friendly NC controller with a digital display, sourced from industry-leading brands. As an NC shearing machine manufacturer, we ensure the controller provides:

- Fast programming of multiple back gauge positions.

- Stroke length optimization and stroke counting on the screen.

- Storage of cutting profiles for repeat jobs.

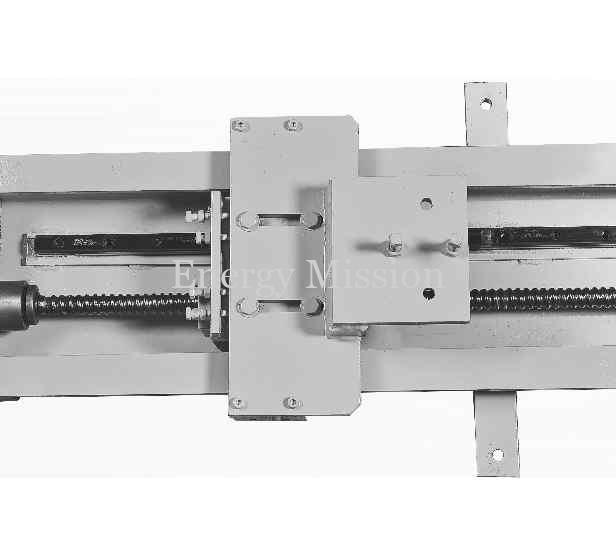

High-Precision Back Gauge System

Accuracy is critical in metal fabrication, and our NC shearing machine excels with a high-precision back gauge system featuring:

- Repeatability of ±0.1mm: Ensures consistent cuts across large batches.

- High-Speed Movement: Driven by an AC servo drive with a timer belt for quick positioning.

- Hardened Ball Screws and Linear Motion Bearings: Guarantee smooth operation and reliability.

- Automatic Back Gauge Retraction: Improves efficiency by retracting after securing the sheet.

Durable Construction

Built to withstand tough industrial environments, our NC shearing machines feature:

- A robust frame made from ultrasonically tested IS 2062 grade steel for superior rigidity.

- Hardened components for long-term durability.

- Low-noise hydraulic systems with compact manifolds for efficient performance.

Low Noise and Smooth Operation

Our NC shearing machines are designed for operator comfort:

- Low-noise hydraulic systems ensure a quieter working environment.

- Smooth operation reduces operator fatigue during long shifts.

- Pre-calibrated blade gap adjustments simplify setup and maintenance.

Applications of Our NC Shearing Machine

The versatility of our NC shearing machine makes it suitable for a wide range of industries and applications:

- Automotive Industry: Precision cutting for car body panels, chassis components, and brackets using our NC shearing machine.

- Construction and Infrastructure: Shearing steel beams and plates for structural frameworks, roofing, and cladding with speed and accuracy.

- Aerospace Manufacturing: High-accuracy cutting for lightweight materials like aluminum and titanium.

- General Fabrication: Flexible enough for custom parts, prototypes, or large-scale production runs.

- Shipbuilding: Powerful cutting capacity for thick marine-grade steel plates.

- Electrical and Electronics: Burr-free cuts for enclosures, panels, and mounting plates for precision components.

Technical Specifications

| Feature | Details |

|---|---|

| Cutting Capacity | 3 mm to 25 mm thickness (customizable) |

| Cutting Length | 1250 mm to 7000 mm (customizable) |

| Rake Angle Adjustment | Automatic via NC controller |

| Blade Clearance Adjustment | Pre-calibrated, manually adjustable or automatic |

| Stroke Length Control | Programmable via NC controller</td<> |

| Back Gauge Accuracy | ±0.1mm repeatability |

| Back Gauge Drive | AC servo drive with hardened ball screws and timer belt |

| Controller | NC controller with digital display |

| Back Gauge Features | Multi-position programming, stroke counting, automatic retraction |

| Construction | Ultrasonically tested IS 2062 grade steel frame, hardened components |

| Power Supply | Customizable (e.g., 220V, 380V, 50/60Hz) |

Note: Specifications can be customized. Contact us for detailed configurations.

Benefits of Our NC Shearing Machine

Investing in our NC shearing machine offers numerous advantages:

- Enhanced Productivity: NC-controlled automation in our NC shearing machine reduces setup times and increases throughput.

- Superior Cut Quality: Achieve burr-free, precise cuts with minimal waste, reducing secondary finishing costs.

- Cost-Effective Operation: Energy-efficient design lowers operating costs, a key focus as an NC shearing machine manufacturer.

- Operator-Friendly Design: Intuitive NC controller simplifies operation, reducing fatigue.

- Scalable Performance: Customizable configurations suit growing business needs with support from your NC shearing machine supplier.

- Sustainability: Precision cutting minimizes material waste, promoting eco-friendly production.

Why Partner with Us as Your NC Shearing Machine Supplier?

As a leading NC shearing machine manufacturer and NC shearing machine supplier, we provide distinct advantages:

- Proven Expertise: Decades of experience in designing reliable NC shearing machines.

- Global Support: Comprehensive after-sales service, including installation, training, and maintenance.

- Competitive Pricing: Advanced technology at affordable prices, ensuring value as an NC shearing machine supplier.

- Innovation-Driven: Continuous R&D to incorporate the latest advancements in NC technology.

- Tailored Customization: Solutions designed to meet your specific production needs.

Optional Accessories and Upgrades

Enhance your NC shearing machine with optional features:

- Extended back gauge length for larger sheets.

- Pneumatic sheet support systems for thin sheets.

- Laser cutting line guide for precise alignment.

- Safety enhancements like guards and light curtains.

- Custom blade materials for specific applications.

Contact us to explore the best accessories for your needs.

How to Choose the Right NC Shearing Machine

Selecting the right NC shearing machine depends on several factors:

- Material Requirements: Match cutting capacity to your materials.

- Production Volume: High-speed automation for large volumes.

- Automation Needs: Look for intuitive NC controllers.

- Durability/Support: Choose a reliable NC shearing machine manufacturer.

- Budget/ROI: Balance costs with long-term savings.

Maintenance Tips for Optimal Performance

Maintain your NC shearing machine with these tips:

- Regularly inspect and replace blades to maintain cut quality.

- Lubricate moving parts to reduce wear.

- Clean the machine to prevent debris buildup.

- Monitor hydraulic systems for leaks or contamination.

- Schedule professional servicing to address potential issues early.