Improve your metal fabrication process with our state-of-the-art CNC Shearing Machine, designed for unparalleled precision, productivity, and versatility. As a trusted CNC shearing machine manufacturer and supplier, we deliver advanced technology that meets the diverse needs of modern industries. Whether you’re cutting thin sheets or thick plates, our CNC hydraulic shearing machine ensures consistent, high-quality results with every operation, helping you optimize your workflow and achieve superior outcomes in your production line.

Why Choose Our CNC Shearing Machine?

Our CNC shearing machines are meticulously engineered to enhance operational efficiency, reduce material waste, and deliver exceptional cut quality. Here’s what sets us apart as a leading CNC shearing machine manufacturer in the industry:

- Superior Precision Cutting: Achieve clean, accurate cuts with minimal burrs, thanks to our advanced variable rake angle technology, ensuring high-quality output across a variety of materials.

- Versatile Performance Across Applications: Suitable for a wide range of materials, including stainless steel, aluminum, mild steel, brass, copper, and other alloys, making it an ideal solution for diverse industries.

- Robust and Durable Construction: Built with high-quality components like hardened ball screws and LM guides, our machines are designed for durability and long-term reliability in demanding industrial environments.

- User-Friendly Operation and Automation: Intuitive touch screen controls and automation features simplify operation, reduce setup times, and enhance productivity, even for complex cutting tasks.

- Customizable Solutions for Your Needs: Tailored configurations to meet your specific requirements, ensuring seamless integration into your existing production line and workflows.

Key Features of Our CNC Shearing Machine

Our CNC shearing machines are packed with advanced features that make them stand out in the market. Below is a closer look at the technology and capabilities that ensure unparalleled performance:

Variable Rake Angle Type Guillotine Shearing Mechanism

The variable rake angle design is a hallmark of our CNC shearing machine, offering flexibility for cutting both thin and thick sheets with precision. The automatic rake angle adjustment, controlled via the machine’s advanced controller, allows for optimal cutting angles based on material type and thickness. This feature minimizes distortion, reduces shear force, and ensures cleaner cuts, even on challenging materials like high-tensile steel. Whether you’re working on delicate thin sheets or robust thick plates, this mechanism delivers consistent results, reducing the need for secondary finishing processes.

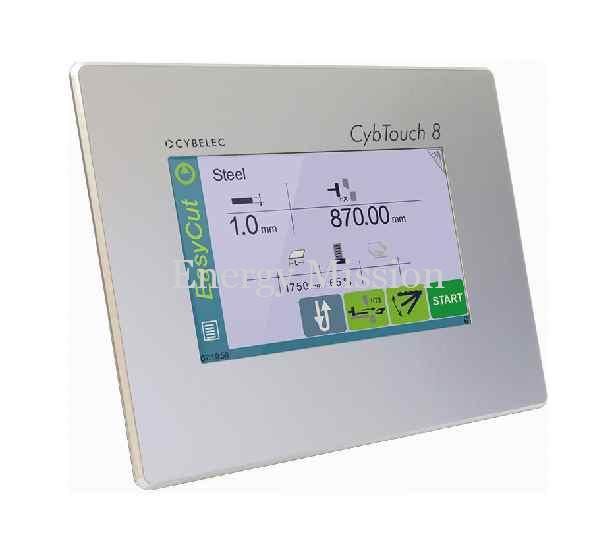

Advanced 7” Touch Screen Shear Controller

Our machines are equipped with a 7” touch screen shear controller from industry-leading brands like Cybelec or Schneider, providing operators with an intuitive and user-friendly interface. The color LCD screen allows for easy programming and precise control of critical parameters such as rake angle, blade clearance, and stroke length. Operators can quickly input specifications, save cutting profiles for repeat jobs, and monitor real-time cutting data, ensuring a seamless and efficient workflow. This advanced control system reduces the learning curve for operators and minimizes the risk of errors during production, making it ideal for both experienced technicians and those new to CNC shearing operations.

Automatic Adjustments for Maximum Efficiency

Automation is at the core of our CNC hydraulic shearing machine, designed to streamline operations and boost productivity. Key automatic features include:

- Rake Angle Adjustment: Automatically adjusts the rake angle based on material thickness and type, ensuring optimal cutting performance and reducing wear on the blades.

- Blade Clearance Adjustment: Automatically sets the perfect blade gap for each cut, enhancing cut quality and extending blade lifespan by minimizing unnecessary stress.

- Stroke Length Control: Optimizes the stroke length for each cutting task, reducing cycle times and energy consumption while maintaining precision.

These automated adjustments eliminate the need for manual intervention, allowing operators to focus on production rather than setup. As a result, turnaround times are faster, and overall throughput is significantly improved, making our machines a valuable asset for high-paced production environments.

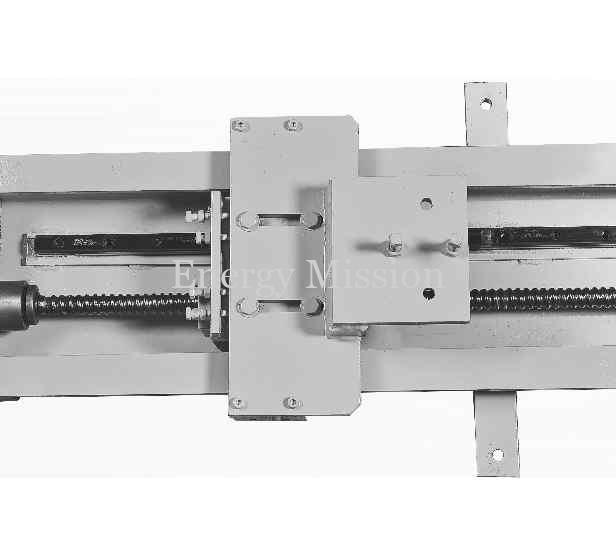

High-Precision Back Gauge System

Accuracy is critical in metal fabrication, and our CNC shearing machine delivers with a high-precision back gauge system. Key features include:

- Repeated Position Accuracy: Achieves a repeatability of ±0.1mm, ensuring consistent cuts across large batches of material.

- High-Speed Movement: Powered by an AC servo drive, the back gauge moves quickly and accurately, reducing setup times and increasing production efficiency.

- Advanced Functionality: Includes automatic back gauge retraction after holding the sheet, multiple back-gauge positions, and on-screen stroke counting for enhanced control and flexibility.

The back gauge system is designed to handle complex cutting patterns with ease, making it ideal for both simple straight cuts and intricate fabrication tasks. Its precision and speed make it a valuable asset for high-volume production environments where accuracy cannot be compromised.

Durable Construction for Long-Term Performance

Built with durability in mind, our CNC shearing machines feature a smooth and sturdy back gauge assembly, incorporating hardened ball screws, LM guides, and timer belts. These high-quality components ensure stability and reliability, even under the rigors of heavy-duty industrial use. The machine’s frame is constructed from premium-grade steel, providing a solid foundation that minimizes vibration and maintains alignment during operation. This robust construction not only extends the machine’s lifespan but also ensures consistent performance over time, making it a smart investment for any fabrication shop looking to improve its operational efficiency.

Applications of Our CNC Shearing Machine

The versatility of our CNC hydraulic shearing machine makes it suitable for a wide range of industries and applications. Below are some of the key sectors that benefit from its precision and performance:

- Automotive Industry: In the automotive sector, precision and consistency are paramount. Our CNC shearing machine is used to cut sheet metal for car body panels, chassis components, brackets, and other structural elements. The ability to handle different materials and thicknesses with high accuracy ensures that parts meet strict tolerances and quality standards.

- Construction and Infrastructure: From cutting steel beams for structural frameworks to shearing plates for roofing, cladding, and architectural panels, our machines play a vital role in the construction industry. The high-speed back gauge and automatic adjustments enable fast and accurate cuts, improving project timelines.

- Aerospace Manufacturing: The aerospace industry requires precision cutting for lightweight materials like aluminum, titanium, and advanced composites. Our CNC shearing machines provide the accuracy needed to meet stringent aerospace standards while maintaining high productivity levels.

- General Fabrication: For general fabrication shops, our machines offer flexibility to handle a wide range of materials and thicknesses, delivering consistent results with minimal setup time.

- Shipbuilding: In shipbuilding, where large metal plates are often required, our machines provide the power and precision needed to cut thick sheets with ease, ensuring clean cuts for marine-grade steel.

- Electrical and Electronics: The electrical and electronics industry benefits from burr-free cuts with tight tolerances for enclosures, panels, and mounting plates, ensuring a high level of precision and a clean finish.

Technical Specifications

| Feature | Details |

|---|---|

| Cutting Capacity | Suitable for thin to thick sheets (customizable based on requirements) |

| Rake Angle Adjustment | Automatic via controller, adjustable for material and thickness |

| Blade Clearance Adjustment | Automatic, controlled through the touch screen interface |

| Stroke Length Control | Automatic, optimized for efficiency and energy savings |

| Back Gauge Accuracy | ±0.1mm repeatability for precise positioning |

| Back Gauge Drive | High-speed AC servo drive for quick and accurate movement |

| Controller | 7” touch screen (Cybelec/Schneider) with color LCD display |

| Back Gauge Features | Automatic retraction, multiple positions, stroke counting on screen |

| Construction | Hardened ball screws, LM guides, and timer belts for durability |

| Power Supply | Customizable based on regional requirements (e.g., 220V, 380V, 50/60Hz) |

Note: Specifications can be customized to meet your specific needs. Contact us for detailed configurations and optional features.

Benefits of Our CNC Shearing Machine

Investing in our CNC shearing machine offers numerous advantages that can transform your metal fabrication process:

- Enhanced Productivity Through Automation: Automation features like automatic rake angle adjustment, blade clearance adjustment, and stroke length control reduce setup times and increase throughput, keeping production on schedule.

- Improved Cut Quality for Better Results: Achieve burr-free, precise cuts with minimal material waste, reducing the need for secondary finishing processes and lowering production costs.

- Cost-Effective Operation and Maintenance: Energy-efficient design and durable components lower operating and maintenance costs, providing a strong return on investment.

- Operator-Friendly Design for Ease of Use: Intuitive touch screen controls minimize operator fatigue and reduce the learning curve, ensuring consistent results across your team.

- Scalable Performance for Growing Businesses: Customizable configurations allow our machines to scale with your business, accommodating increased production demands.

- Reduced Material Waste for Sustainability: Precision cutting minimizes material waste, supporting cost-effective and environmentally friendly production practices.

Why Partner with Us as Your CNC Shearing Machine Supplier?

As a leading CNC shearing machine manufacturer, we are committed to delivering innovative solutions that drive your success. Here’s why businesses worldwide choose us as their preferred CNC shearing machine supplier:

- Industry Expertise: Decades of experience in designing and manufacturing high-performance CNC shearing machines.

- Global Support: Comprehensive after-sales service, including installation, training, and maintenance.

- Competitive Pricing: Advanced technology at affordable prices, ensuring maximum value for your investment.

- Innovation-Driven: Continuous R&D to incorporate the latest advancements in automation and material handling.

- Customization: Tailored solutions to meet your specific requirements, ensuring optimal performance in your application.

Optional Accessories and Upgrades

Enhance your CNC shearing machine with optional features such as:

- Extended back gauge length for larger sheets.

- Front feeding tables for easier material handling.

- Pneumatic sheet support systems for thin sheets.

- Laser cutting line guide for precise alignment.

- Custom blade materials for specific applications.

- Safety enhancements like guards and light curtains.

Contact us to discuss which accessories best suit your production needs.

How to Choose the Right CNC Shearing Machine

Selecting the right CNC shearing machine depends on several factors:

- Assess Material Requirements: Match cutting capacity to your materials.

- Evaluate Production Volume: High-speed automation for large volumes; simpler models for smaller runs.

- Consider Automation Needs: Look for user-friendly interfaces and automated features.

- Prioritize Durability and Support: Choose a reliable manufacturer with strong after-sales support.

- Budget and ROI: Balance upfront costs with long-term savings.

Maintenance Tips for Optimal Performance

Maintain your CNC hydraulic shearing machine with these tips:

- Regularly inspect and replace blades to ensure cut quality.

- Lubricate moving parts to reduce wear.

- Clean the machine to prevent debris buildup.

- Monitor hydraulic systems for leaks or contamination.

- Schedule professional servicing for longevity.

Get a Quote Today

Ready to experience the precision and efficiency of our CNC shearing machine? Contact us today to request a quote or schedule a demo.