Hydraulic Press Brake – Precision Metal Bending Solutions

Looking for a trusted Hydraulic Press Brake Machine Manufacturer or Supplier? Our Hydraulic Press Brake offers exceptional precision, durability, and efficiency for all your sheet metal bending needs. Designed to serve industries worldwide, this machine combines advanced hydraulic technology with robust construction to deliver reliable performance. Whether you’re seeking a Hydraulic Press Brake or exploring cutting-edge CNC Press Brake Machine options, we provide high-quality solutions tailored to your fabrication requirements.

Why Choose Us as Your Hydraulic Press Brake Manufacturer?

As a leading Hydraulic Press Brake Manufacturer, we bring decades of expertise to deliver machines that exceed industry standards. Operating from a modern 4,500-square-meter facility in Ahmedabad, Gujarat, India, our team of over 150 skilled professionals—including 15 qualified engineers—ensures every machine reflects innovation and quality. This commitment positions us as a top Hydraulic Press Brake Supplier for businesses globally.

Our Hydraulic Press Brake is engineered for versatility, offering powerful bending capabilities with precise control. Its rugged design and advanced hydraulic system make it suitable for small workshops and large industrial setups alike, providing a cost-effective solution for metal forming.

Key Features of the Hydraulic Press Brake

- Advanced Hydraulic System

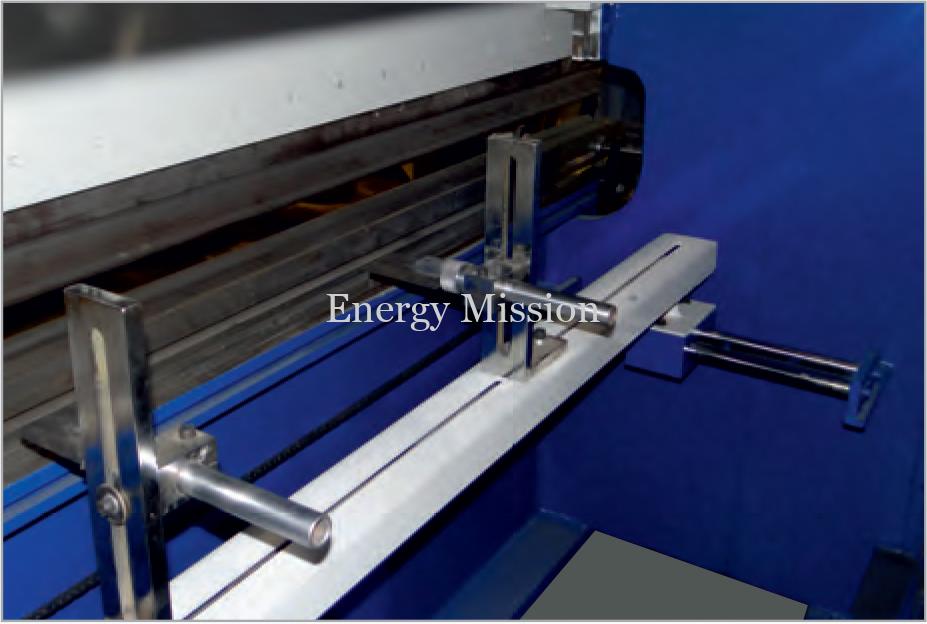

Powered by twin hydraulic cylinders, our Hydraulic Press Brake delivers consistent force for accurate bending. The hydraulic system ensures smooth operation, making it ideal for heavy-duty applications. - Robust Construction

Built with ultrasonically and tensile-tested IS:2062 grade steel, this machine offers exceptional durability and stability. The frame is machined for single-reference accuracy, ensuring long-term reliability. - High Tonnage Capacity

Available in a range of tonnage options, the Hydraulic Press Brake Machine can handle various sheet metal thicknesses and lengths, meeting diverse fabrication demands with ease. - User-Friendly Operation

Designed for efficiency, the machine features intuitive controls that reduce setup time and enhance operator productivity, bridging the gap between manual and fully automated systems like a CNC Press Brake Machine. - Cost-Effective Performance

Compared to advanced CNC Press Brake Machines, our hydraulic models provide precision and power at a lower cost, making them an excellent choice for businesses optimizing their budget.

Applications of the Hydraulic Press Brake

The Hydraulic Press Brake is a versatile tool used across multiple industries, including:

- Automotive: Forming chassis components, brackets, and panels with precision.

- Construction: Bending structural steel and metal frames.

- Furniture Manufacturing: Crafting metal supports and frames.

- Aerospace: Producing high-strength, lightweight parts.

- General Fabrication: Tackling custom bending projects with accuracy.

As a premier Hydraulic Press Brake Supplier, we ensure our machines meet the specific needs of each sector, delivering consistent results for every application.

Hydraulic Press Brake vs. CNC Press Brake Machine: A Comparison

Choosing between a Hydraulic Press Brake machine and a CNC Press Brake Machine depends on your production goals. Here’s how they compare:

Hydraulic Press Brake

- Control System: Manual or semi-automatic operation with hydraulic power, requiring operator input for settings.

- Cost: More affordable than CNC models, perfect for budget-conscious businesses.

- Skill Level: Requires moderate operator expertise for setup and adjustments.

- Speed: Slower than CNC but efficient for small to medium runs.

- Precision: Offers reliable accuracy with mechanical synchronization, though less advanced than CNC.

CNC Press Brake Machine

- Control System: Fully automated with Computer Numerical Control (CNC), supporting complex bending sequences and real-time adjustments.]

- Cost: Higher investment due to advanced technology.

- Skill Level: Minimal training needed with intuitive programming and automation features.

- Speed: Faster operation with high cylinder ratios and rapid transitions.

- Precision: Uses electro-hydraulic servo systems for superior accuracy and repeatability.

We offer both Hydraulic Press Brakes Machines and CNC Press Brake Machines, giving you the flexibility to select the ideal solution. As a top Hydraulic Press Brake Manufacturer, we specialize in cost-effective hydraulic options, while our CNC models cater to high-precision, high-volume demands.

Why We Stand Out as a Hydraulic Press Brake Supplier

1. Proven Engineering Excellence

With over 20 years of experience, we’ve mastered the design and production of press brakes. Our skilled team continuously innovates to deliver advanced Hydraulic Press Brakes that meet modern industry standards.

2. Customization Options

Every fabrication project is unique. As a leading Hydraulic Press Brake Supplier, we offer tailored solutions—such as tonnage, bed length, and back gauge configurations—to suit your specific needs.

3. Global Presence

Based in Ahmedabad, India, we export to countries like the UAE, Saudi Arabia, and Qatar, reinforcing our reputation as a globally trusted Hydraulic Press Brake Manufacturer.

4. Comprehensive After-Sales Support

Our commitment extends beyond delivery with services like installation, training, and maintenance, ensuring your Hydraulic Press Brake Machine performs optimally for years.

5. Competitive Pricing

We prioritize value, offering premium-quality machines at prices lower than many fully automated CNC systems, making us a cost-effective choice for your bending needs.

Technical Specifications of the Hydraulic Press Brake

The table below outlines the key technical specifications of the Hydraulic Press Brake Machine. Variations may occur based on model and customization. Contact us for details tailored to your requirements.

| Parameter | Specification |

|---|---|

| Tonnage | 40T to 200T (customizable for higher capacities) |

| Bending Length | Up to 4000 mm |

| Down Speed | Up to 80 mm/sec |

| Pressing Speed | Up to 10 mm/sec |

| Return Speede | Up to 70 mm/sec |

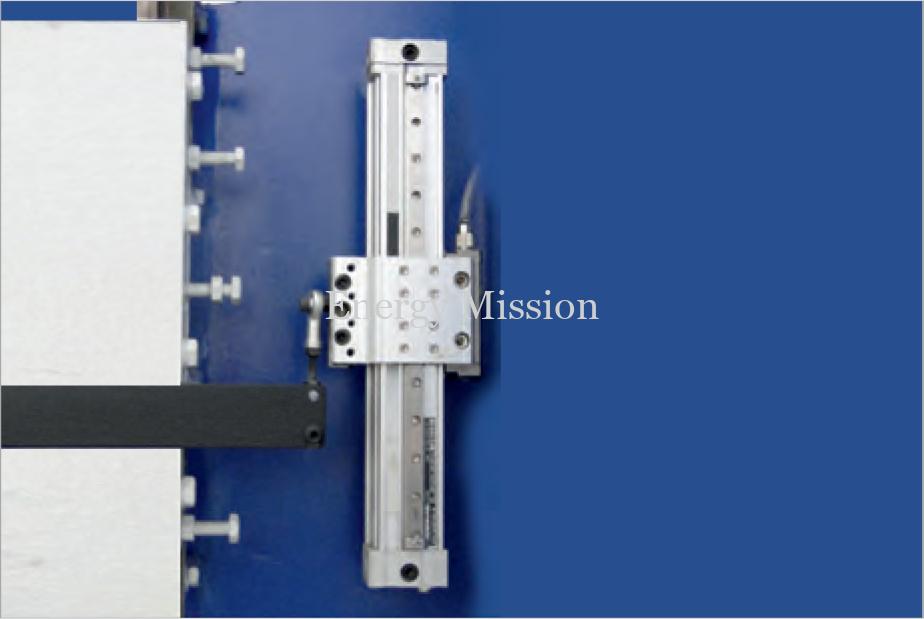

| Back Gauge Range | 0-600 mm (manual or motorized) |

| Back Gauge Accuracy | ±0.1 mm |

| Frame Material | IS:2062 grade steel, ultrasonically tested |

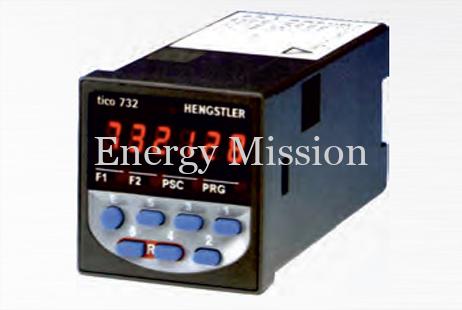

| Control System | Hydraulic with optional NC upgrade |

| Cylinder Configuration | Twin hydraulic cylinders |

| Power Supply | 3-phase, 415V, 50Hz (customizable) |

| Motor Power | 5.5 kW to 15 kW (depending on tonnage) |

| Throat Depth | 250 mm to 400 mm (model-dependent) |

| Stroke Length | 100 mm to 200 mm (adjustable) |

| Weight | 4000 kg to 12000 kg (varies by model) |

| Dimensions (L x W x H) | Approx. 4200 x 1600 x 2400 mm (varies by model) |

Notes:

- Customization: Adjust tonnage, bending length, and features like motorized back gauges or safety systems as needed.

- Optional Features: Includes NC control upgrades, digital displays, and specialized tooling.

- Compliance: Meets international safety and performance standards.

Reach out for a detailed quote or personalized configuration assistance.

How the Hydraulic Press Brake Enhances Productivity

The Hydraulic Press Brake Machine boosts your workflow in several ways:

- Efficient Setup: Hydraulic controls allow quick adjustments, minimizing downtime between tasks.

- Consistent Results: Twin cylinders and a sturdy frame ensure uniform bending, reducing waste.

- Versatile Material Handling: Bends a range of metals, from mild steel to stainless steel, with precision.

- Low Maintenance: Durable components reduce upkeep costs and interruptions.

Competitive Edge Over Other Manufacturers and Suppliers

Compared to competitors, our Hydraulic Press Brake Machine offers a unique combination of affordability, durability, and performance. While some focus solely on high-end CNC solutions, we excel in providing reliable hydraulic machines as a cost-effective alternative. Our India-based manufacturing ensures faster delivery and better pricing than many international brands, giving us an advantage over competitors like Krrass, Accurl, and ADH.

Expand Your Fabrication with a Hydraulic Press Brake

We’re more than just a Hydraulic Press Brake Manufacturer or Supplier—we’re your partner in achieving fabrication excellence. Whether you need a robust Hydraulic Press Brake for your workshop or a high-performance CNC Press Brake Machine for industrial production, we deliver solutions that drive success.