Synchronized Precision for Large-Scale Bending

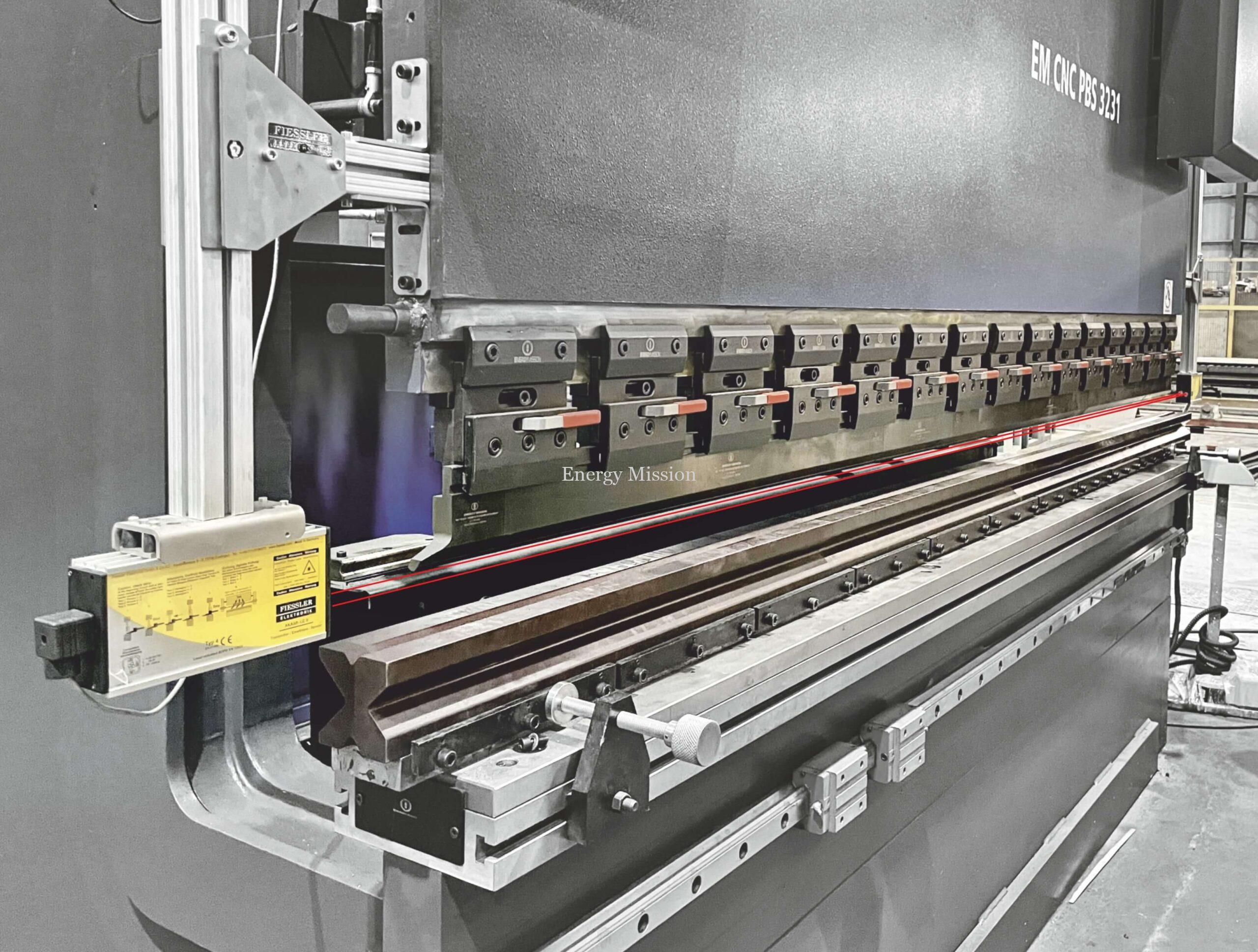

The Tandem CNC Press Brake Machine is a cutting-edge solution in sheet metal fabrication, expertly engineered by a leading Tandem CNC Press Brake Machine Manufacturer. This advanced CNC Press Brake Machine offers synchronized bending capabilities, exceptional precision, and unmatched efficiency, making it the ultimate choice for industries requiring high-performance bending of large or complex workpieces. Whether you’re producing long structural components, light poles, or intricate industrial parts, the Tandem CNC Press Brake Machine delivers superior results tailored to modern manufacturing demands.

Key Features of the Tandem CNC Press Brake Machine

The Tandem CNC Press Brake Machine is designed with innovative features that make it a top-tier offering from any Tandem CNC Press Brake Machine Supplier. Here’s what sets it apart:

Synchronized Dual-Machine Precision

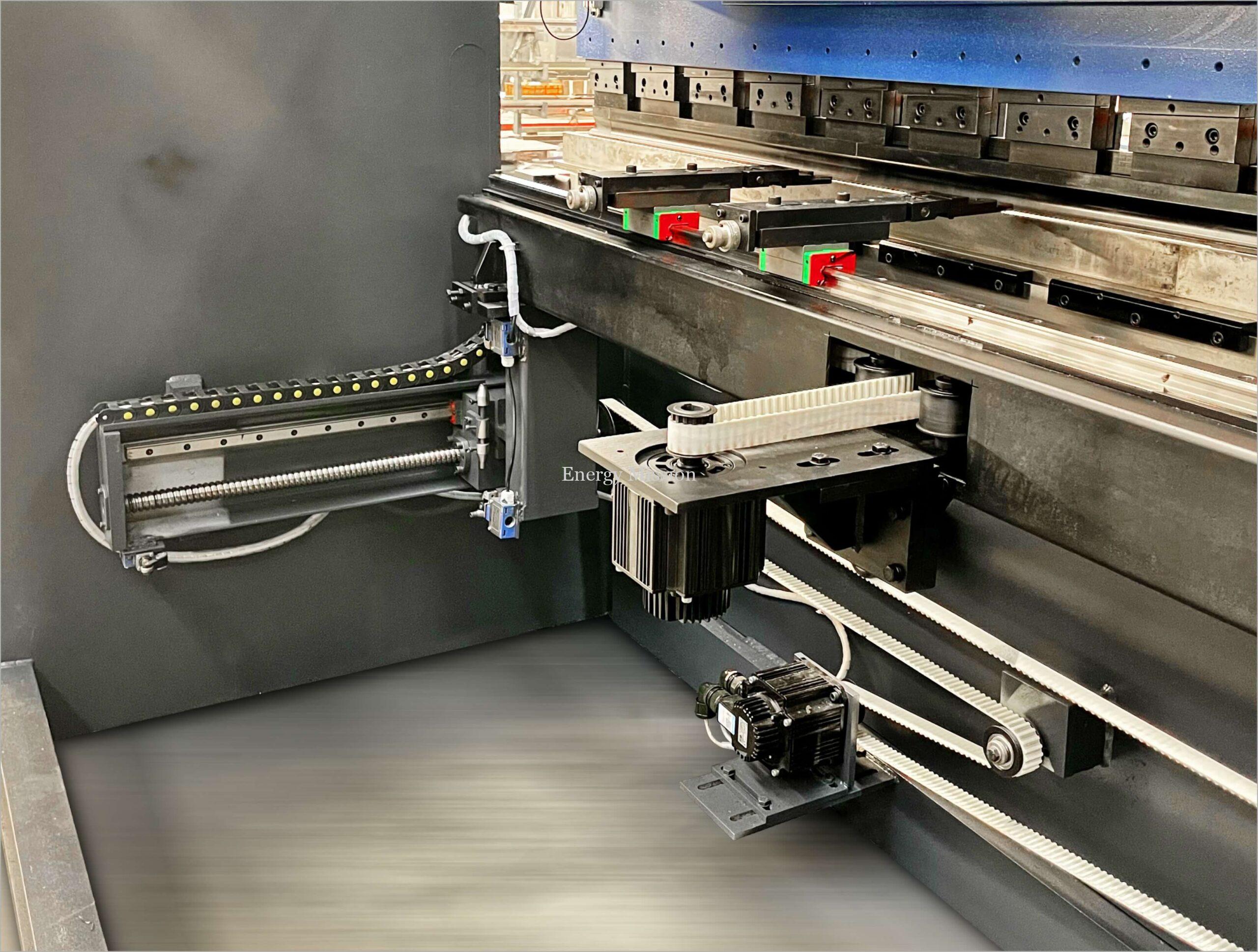

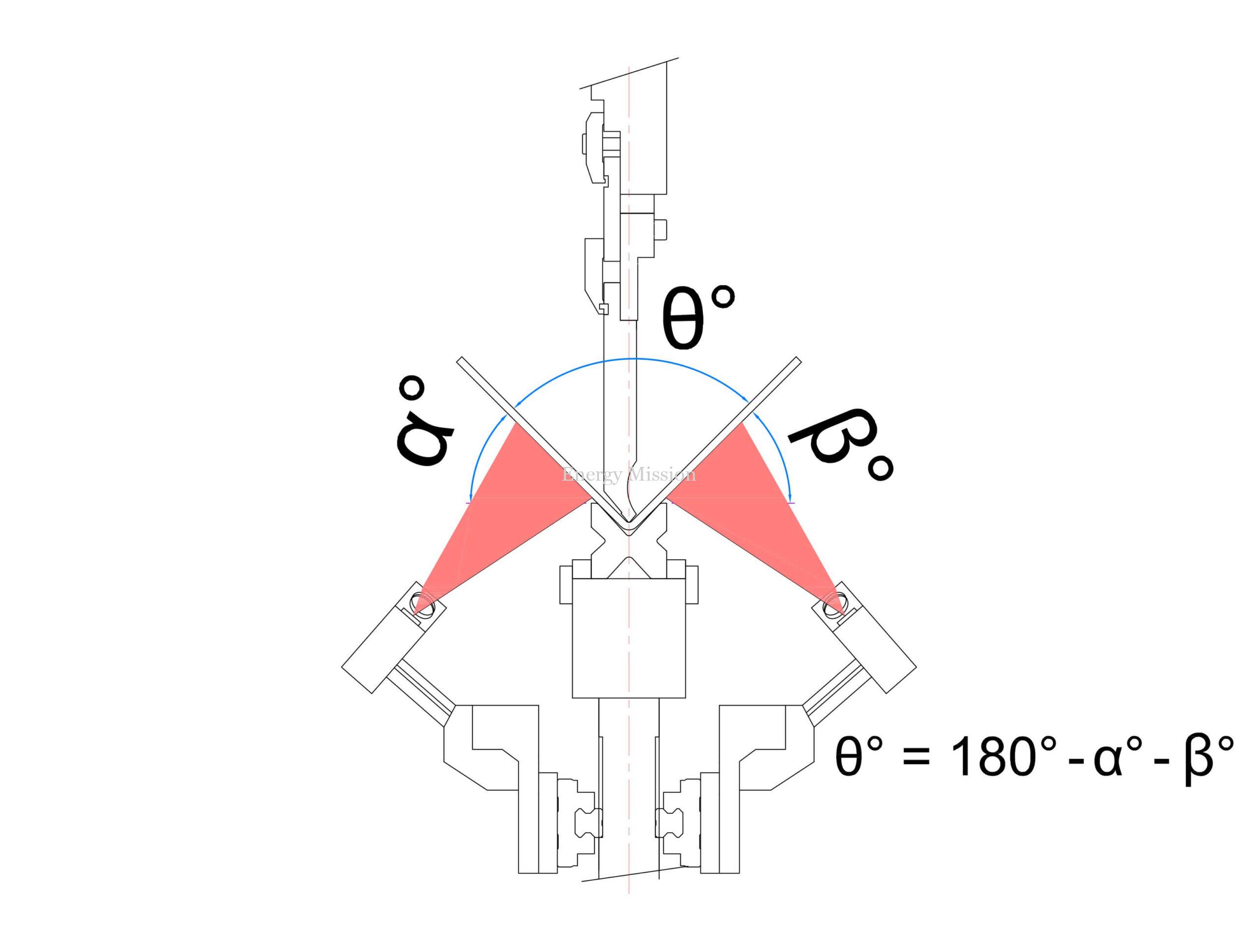

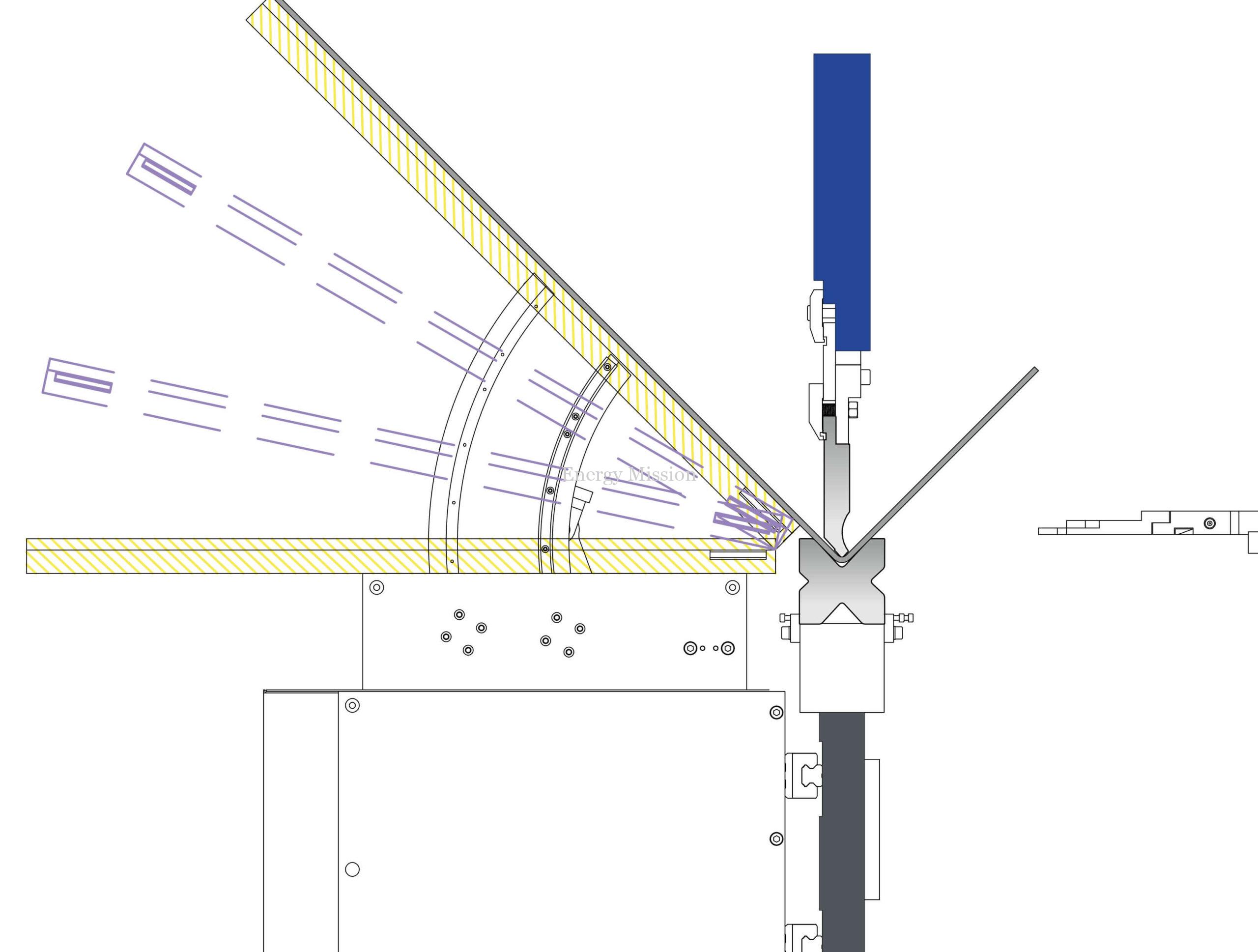

Featuring synchronized 3+1 axis automation (Y1, Y2, X, and R) across two linked machines, the Tandem CNC Press Brake Machine ensures flawless bending accuracy for extended lengths. With beam speeds up to 180 mm/sec and pressing speeds of 12 mm/sec, this CNC Press Brake Machine delivers consistent, high-precision bends on materials like steel, aluminum, and stainless steel. The dual-machine linkage allows for seamless operation, doubling the bending length capacity—ideal for large-scale projects.

Energy-Efficient Technology

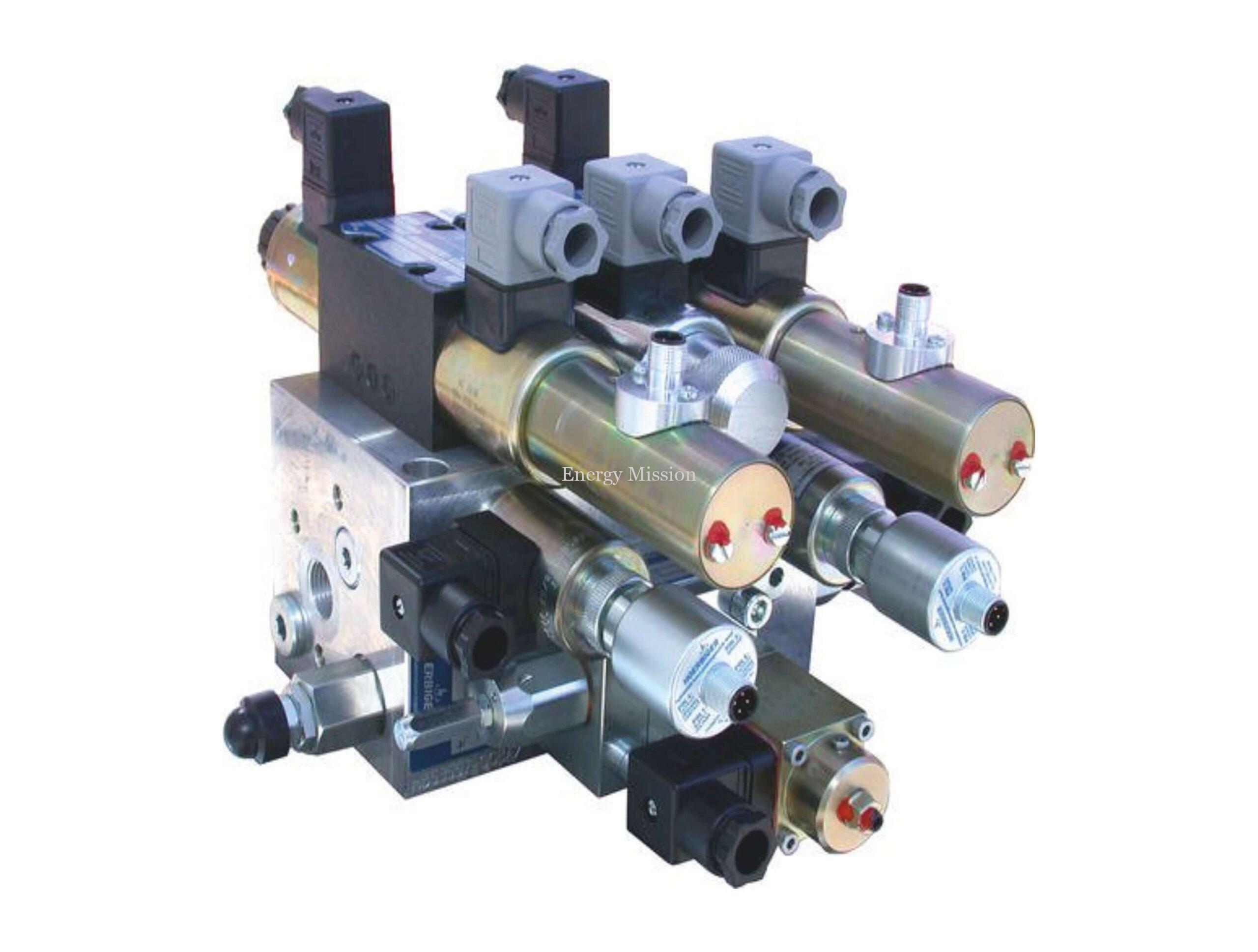

Built with sustainability in mind, the Tandem CNC Press Brake Machine reduces power consumption by up to 45% compared to traditional CNC Press Brake Machines. Its advanced servo-hydraulic system optimizes energy use, lowering operational costs while maintaining peak performance—a standout feature from a premier Tandem CNC Press Brake Machine Manufacturer. This eco-friendly design ensures efficiency without compromise.

Robust and Versatile Construction

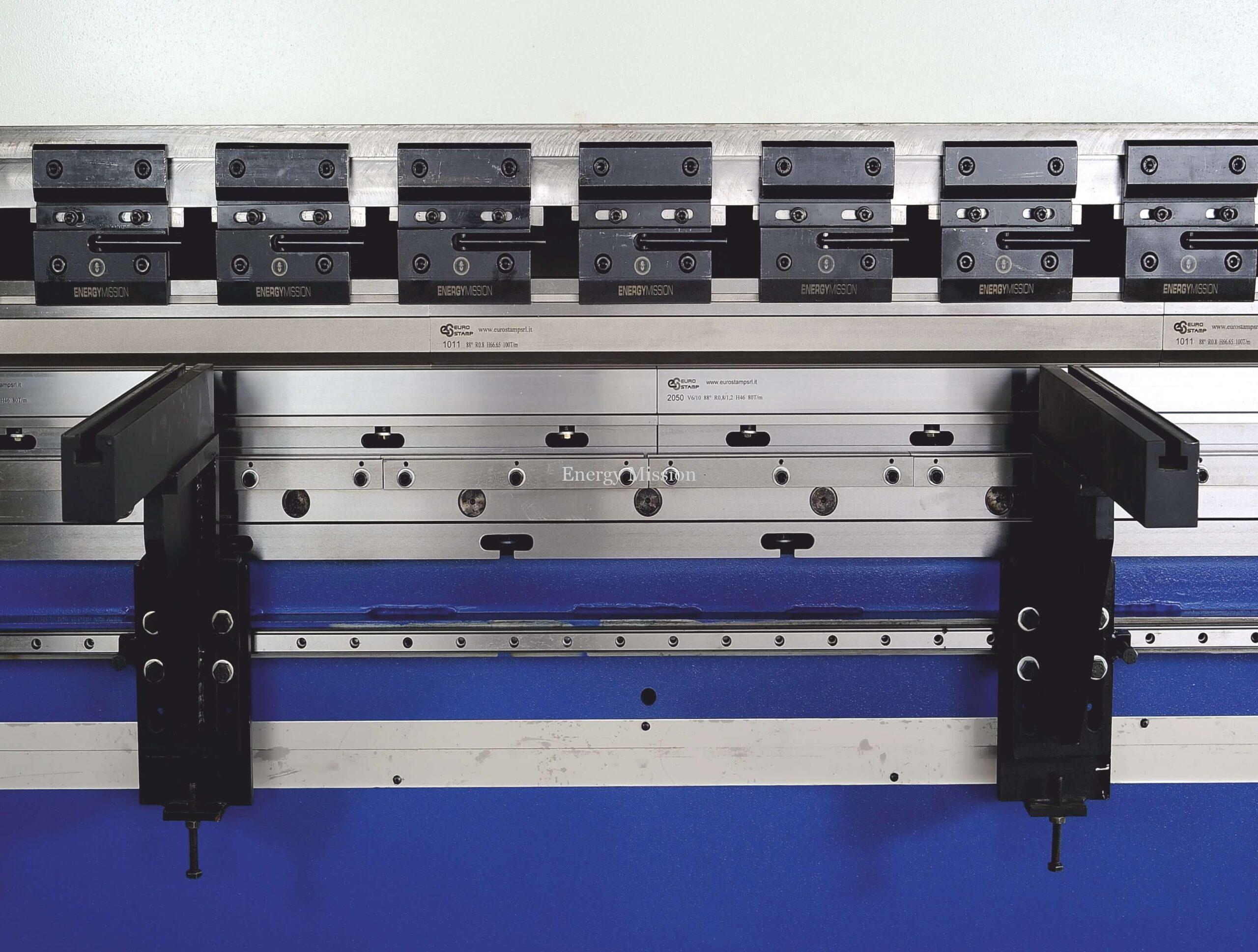

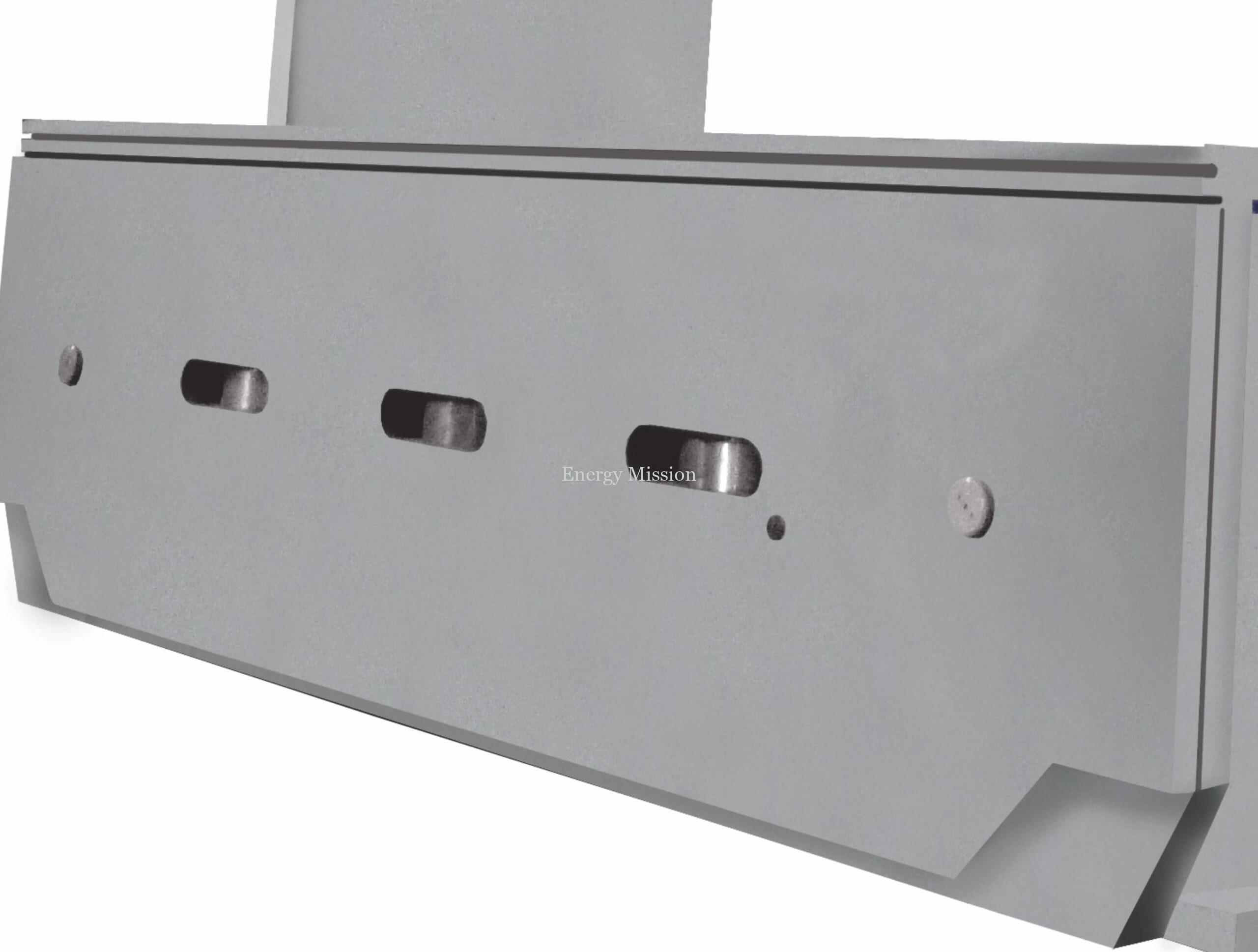

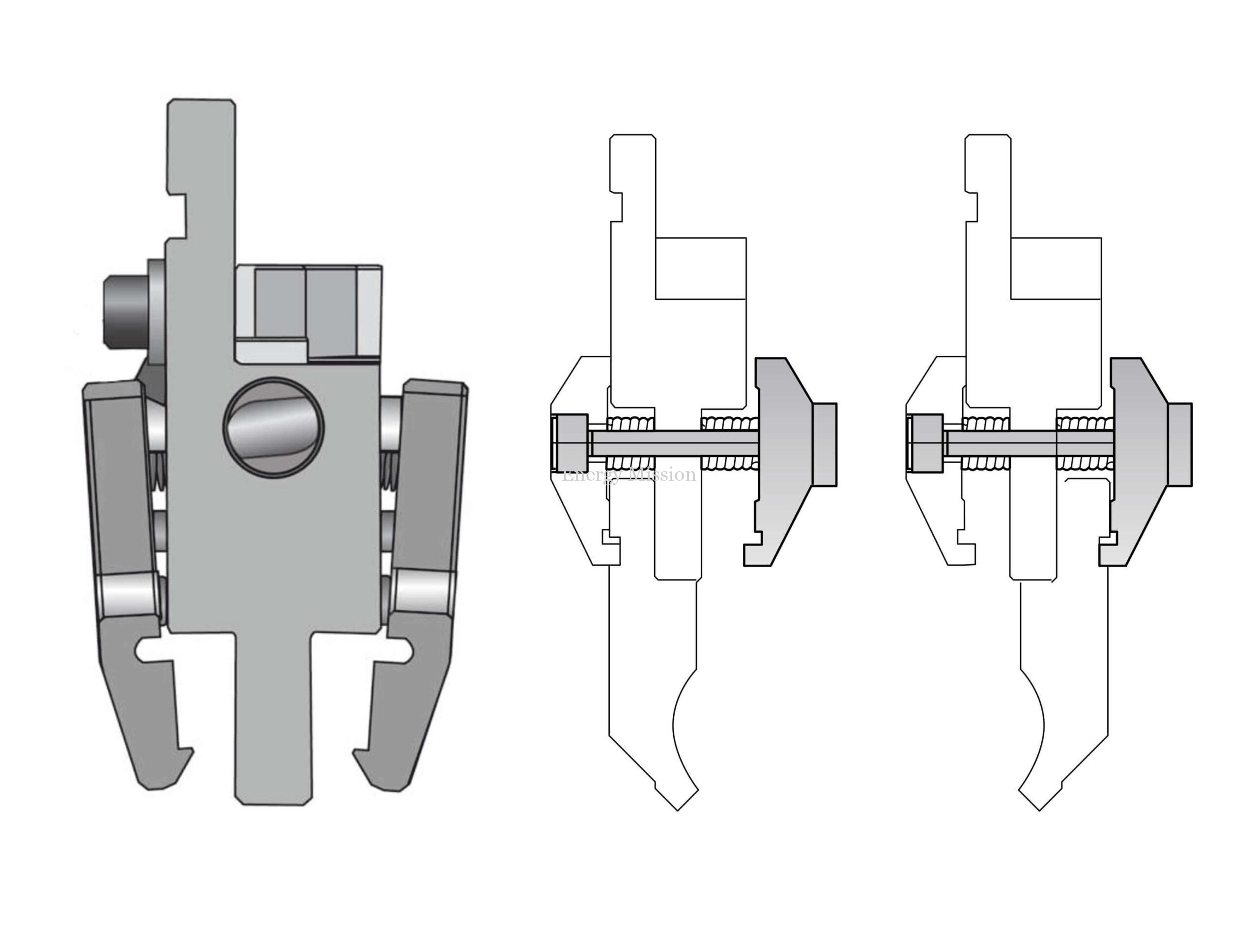

Constructed with an ultrasonically tested IS:2062 grade steel frame, this CNC Press Brake Machine offers exceptional rigidity and durability. Machined on a floor boring machine for single-reference accuracy, it withstands heavy-duty use with minimal deflection. The tandem configuration allows independent or synchronized operation, providing flexibility for both short and long workpieces, enhanced by quick-release clamps and a heavy-duty back gauge.

Advanced CNC Synchronization

The Tandem CNC Press Brake Machine features a sophisticated touchscreen controller (comparable to ESA S 630 or DELEM DA66T), enabling precise synchronization between machines. This intuitive system simplifies programming for complex bending sequences, reducing setup time and boosting productivity—an advantage offered by a trusted Tandem CNC Press Brake Machine Supplier.

Customizable Tandem Configurations

With tonnage capacities ranging from 80 to 2400 tons (in tandem) and bending lengths up to 16 meters, the Tandem CNC Press Brake Machine adapts to diverse project needs. This scalability makes it suitable for small workshops and large industrial setups, ensuring versatility across all fabrication tasks.

Technical Specifications

Here’s a detailed table outlining the Tandem CNC Press Brake Machine’s capabilities:

| Feature | Specification |

|---|---|

| Tonnage Capacity | 80–2400 tons (tandem) |

| Bending Length | Up to 16 meters (tandem) |

| Beam Speed | Up to 180 mm/sec |

| Pressing Speed | 12 mm/sec |

| Back Gauge Range | 500–1000 mm (X-axis) |

| Axis Configuration | 3+1 per machine (Y1, Y2, X, R) |

| Power Efficiency | Up to 45% less than standard models |

| Controller | Advanced touchscreen (comparable to ESA S 630/DELEM DA66T) |

| Frame Material | IS:2062 grade steel, ultrasonically tested |

| Tooling | Hardened & grounded 2’V’/4’V’ die, semi-gooseneck punch |

These specifications showcase the machine’s ability to handle large-scale bending with precision and power.

Why Choose the Tandem CNC Press Brake Machine?

The Tandem CNC Press Brake Machine outperforms competitors like ACCURL, KRRASS, ADHMT, and PrimaPress with its advanced technology and robust design. Here’s why it’s the preferred choice:

- Increased Productivity: Synchronized dual-machine operation doubles bending capacity and speed, ideal for long workpieces like light poles or structural beams.

- Cost Efficiency: Energy savings and low-maintenance design reduce operational costs, enhancing ROI.

- Safety Features: Integrated light curtains and emergency stop systems ensure operator safety during tandem or single-mode use.

- Versatile Operation: Switch between tandem and independent modes seamlessly, catering to both large and small projects.

Sourcing from a top Tandem CNC Press Brake Machine Supplier ensures a machine that excels in performance and adaptability.

Applications Across Industries

The Tandem CNC Press Brake Machine is engineered to meet the demands of various sectors:

- Infrastructure: Perfect for bending long structural beams, bridge components, and light poles with precision.

- Aerospace: Shapes large alloy panels and titanium parts to exact tolerances for aviation applications.

- Automotive: Fabricates oversized chassis and body components efficiently for vehicle production.

- General Fabrication: Handles both short and extended workpieces, offering flexibility for custom projects.

This CNC Press Brake Machine integrates seamlessly into any production line, delivering consistent, high-quality results.

Outperforming the Competition

The Tandem CNC Press Brake Machine surpasses models from ACCURL, KRRASS, ADHMT, and PrimaPress in key areas:

- Energy Efficiency: Reduces power use by up to 45%, outpacing less efficient competitor systems like ACCURL’s standard hydraulic models.

- Structural Strength: Its IS:2062 grade steel frame exceeds the durability of lighter builds from KRRASS and PrimaPress.

- Speed and Synchronization: Faster beam speeds and superior tandem control outperform ADHMT’s tandem offerings.

- Scalability: Offers broader tonnage and length options compared to standardized configurations from competitors.

Crafted by a leading Tandem CNC Press Brake Machine Manufacturer, this machine provides a competitive edge in quality and efficiency.

Additional Benefits

Beyond its core capabilities, the Tandem CNC Press Brake Machine offers:

- Low Maintenance: Engineered for minimal upkeep, reducing downtime and repair costs.

- Tooling Flexibility: Supports quick ‘V’ groove changes and a variety of punches and dies for diverse bending needs.

- Enhanced Precision: Features front sliding sheet supports with LM guides and a ball screw-driven back gauge for smooth, accurate operation.

These benefits make this CNC Press Brake Machine a practical and high-performing investment.

Why Invest in This CNC Press Brake Machine?

Investing in the Tandem CNC Press Brake Machine equips your business with a tool that enhances productivity, reduces costs, and delivers exceptional quality. Whether upgrading equipment or scaling operations, this machine, backed by a top Tandem CNC Press Brake Machine Supplier, keeps you ahead in a competitive market. Its synchronized tandem design, energy-efficient operation, and robust construction ensure reliability for large-scale or custom fabrication projects.

Contact Us for the Tandem CNC Press Brake Machine

Ready to revolutionize your fabrication process? Connect with a trusted Tandem CNC Press Brake Machine Supplier today to explore the Tandem CNC Press Brake Machine. Whether you need pricing, technical specifications, or a live demo of this advanced CNC Press Brake Machine, our team is here to assist. Reach out now to discover how this precision-engineered solution can transform your production capabilities.